Diamond Processing

A rough diamond starts out looking more like a cloudy pebble than a precious gem. Our job is to reveal the fire inside. First, we clean and study each crystal, mapping every tiny flaw and line of growth. Then we trim away the outer layers, piece by piece, until only the pure heart of the stone remains. It may lose almost half its weight, but what’s left is a core that can blaze with colour and light—ready for planning, cutting, and its future life in jewellery.

Planning

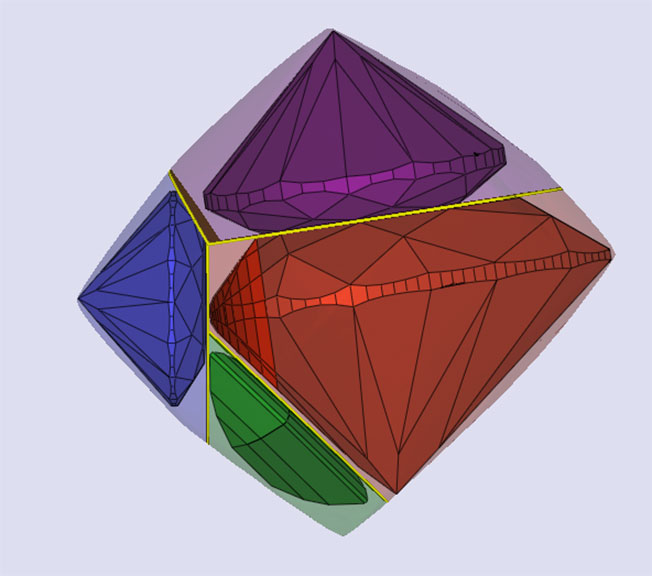

Before a single cut is made, we give each rough diamond a digital check‑up. A 3‑D scanner maps every line and inclusion, then specialised software figures out the best way to slice the stone so we keep the most weight and get the most sparkle. Once the plan looks perfect, a laser marks tiny guide lines on the crystal—turning guesswork into a precise cutting roadmap.

Cutting

Cutting removes the rough stone’s unwanted parts in the cleanest way possible. Skilled craftsmen split the diamond along its natural grain with precision saws, freeing the best sections for polishing. When a cross‑grain cut is required, they use sawing techniques that leave a smooth edge without cracking the crystal.

4P Process

This step gives the diamond its clean outline and perfect proportions. Our team rounds the girdle—the thin band between the crown and pavilion—so the stone starts to look like its final polished shape. While traditional cutters did this entirely by hand, we use computer‑guided machines that keep every angle true and every measurement exact.

.webp)

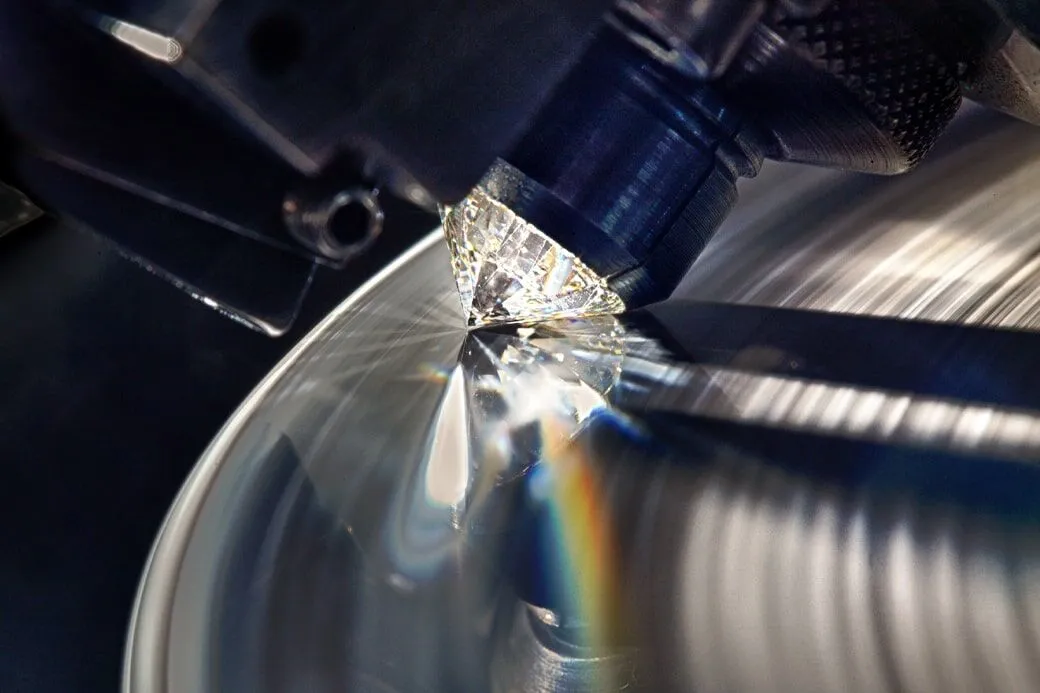

Polishing

This is the moment a diamond starts to shine. Our polishers mount the pre‑shaped stone on a rotating arm and press each side against a fast‑spinning wheel that’s dusted with diamond powder. One by one, they cut the facets—57 in a classic round brilliant—starting with the large table on top, then the 32 crown facets above the girdle, and finally the 24 pavilion facets below. When every angle meets our light‑return test, the diamond leaves the wheel blazing with fire and brilliance.

Diamond Gauging

After polishing, every stone is measured down to a hundredth of a millimetre. Digital calipers record its diameter, depth, and table size, while software checks that each angle matches the original plan. These exact numbers go into the grading report, proving the diamond’s proportions and ensuring every piece in an order lines up perfectly.

Final Produce

After days of careful work, the journey ends with a flawless, brilliantly polished diamond—ready to set, certify, or treasure just as it is.